OUR TECHNOLOGIES

3D printing technology without borders is based on a combination of specially designed and implemented solutions

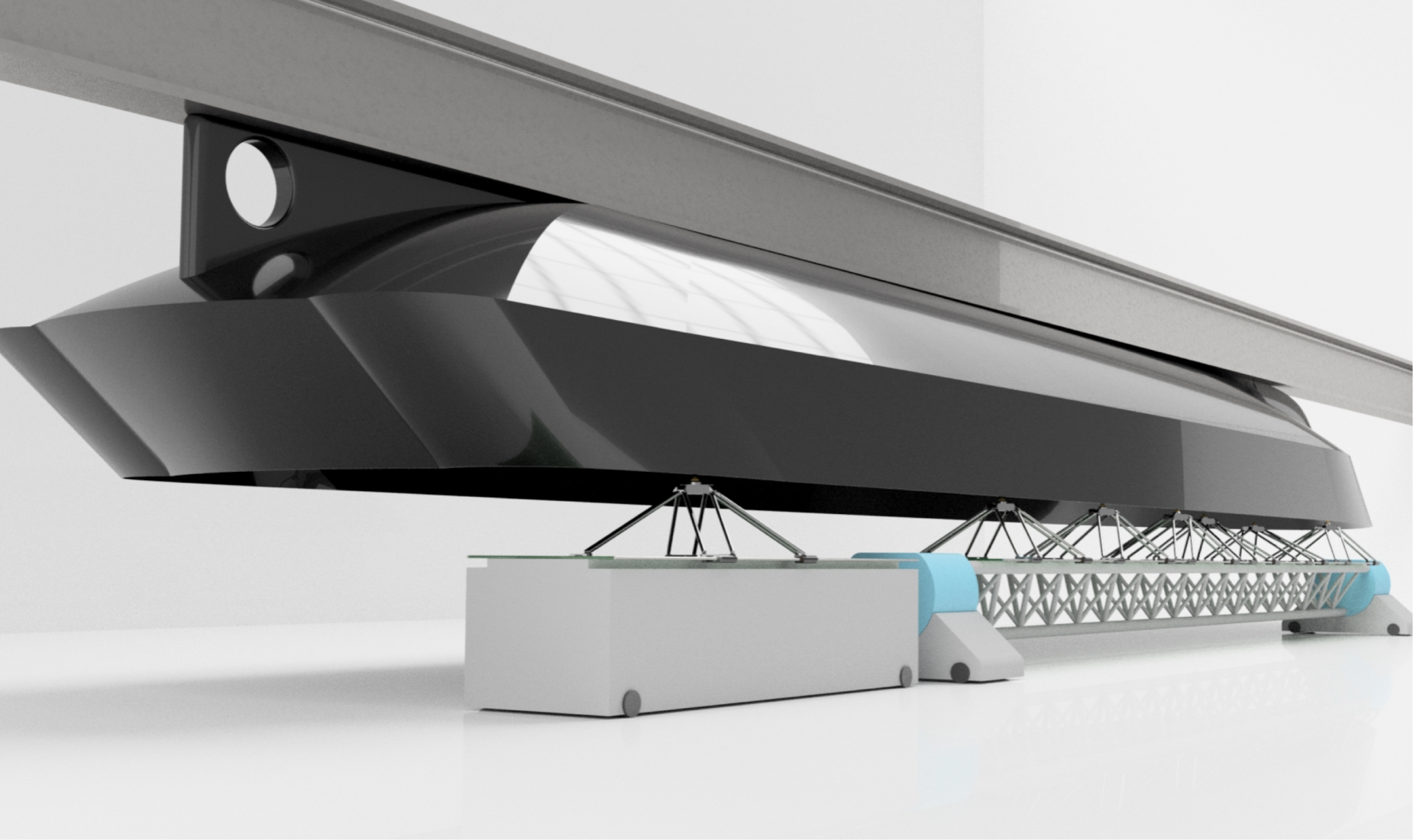

A unique kinematic scheme

The patented kinematic scheme, created specifically for this project, has a number of advantages over analogues:

- It is rational (price /quality);

- Greatly simplifies the design of a 3D printer;

- Allows you to manufacture 3D printer farms (many printers on the same chassis).

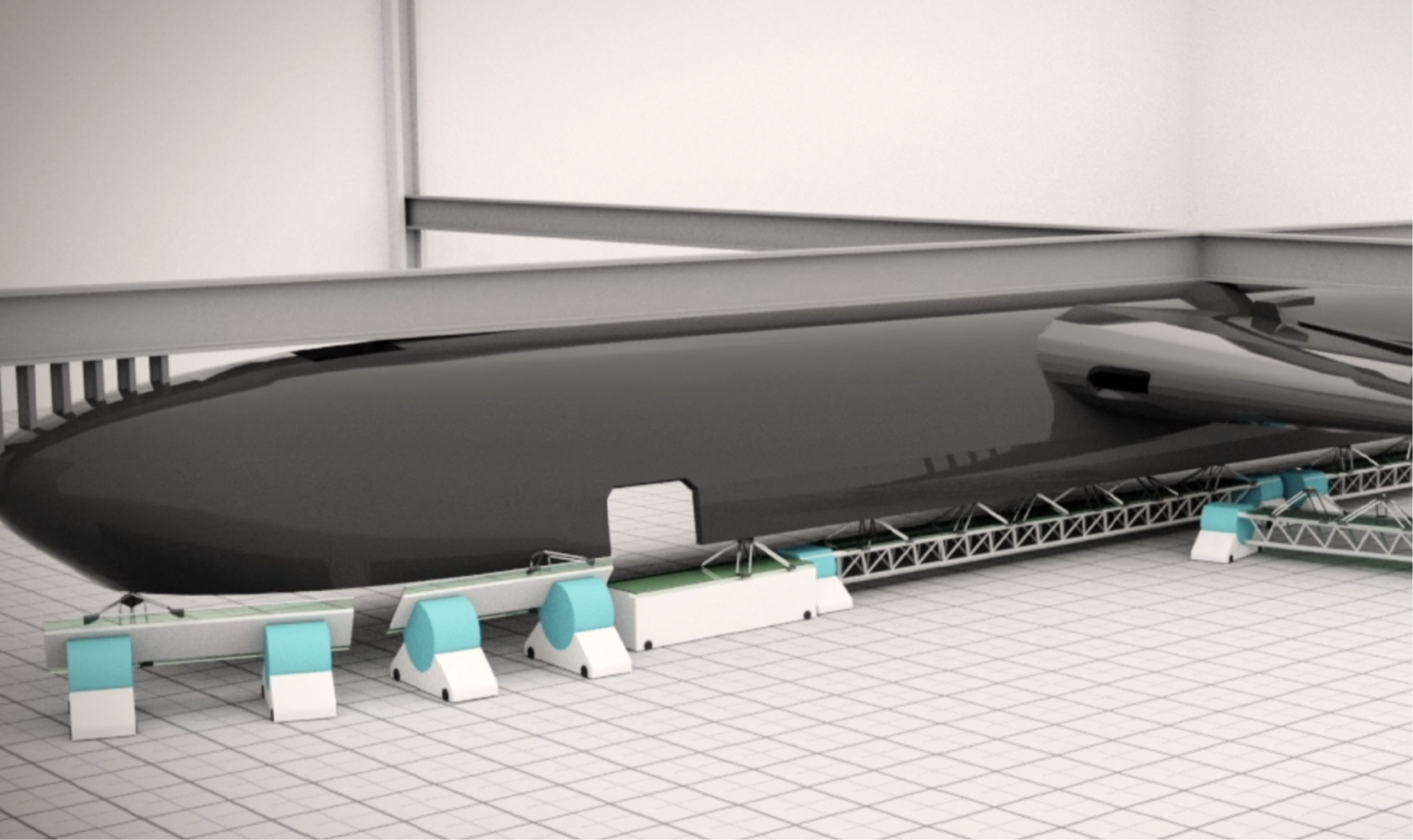

A swarm of self-propelled robot printers

The standard manufacturing technology for large-sized products involves their creation by an additive method with a single printhead. At the same time, this process takes several months.

The use of self-organizing robots, a “swarm”, which print large parts (forms for laying out composites) at the same time, allows you to speed up their creation several dozen times and produce the same product in a few weeks (with a large number of printers).

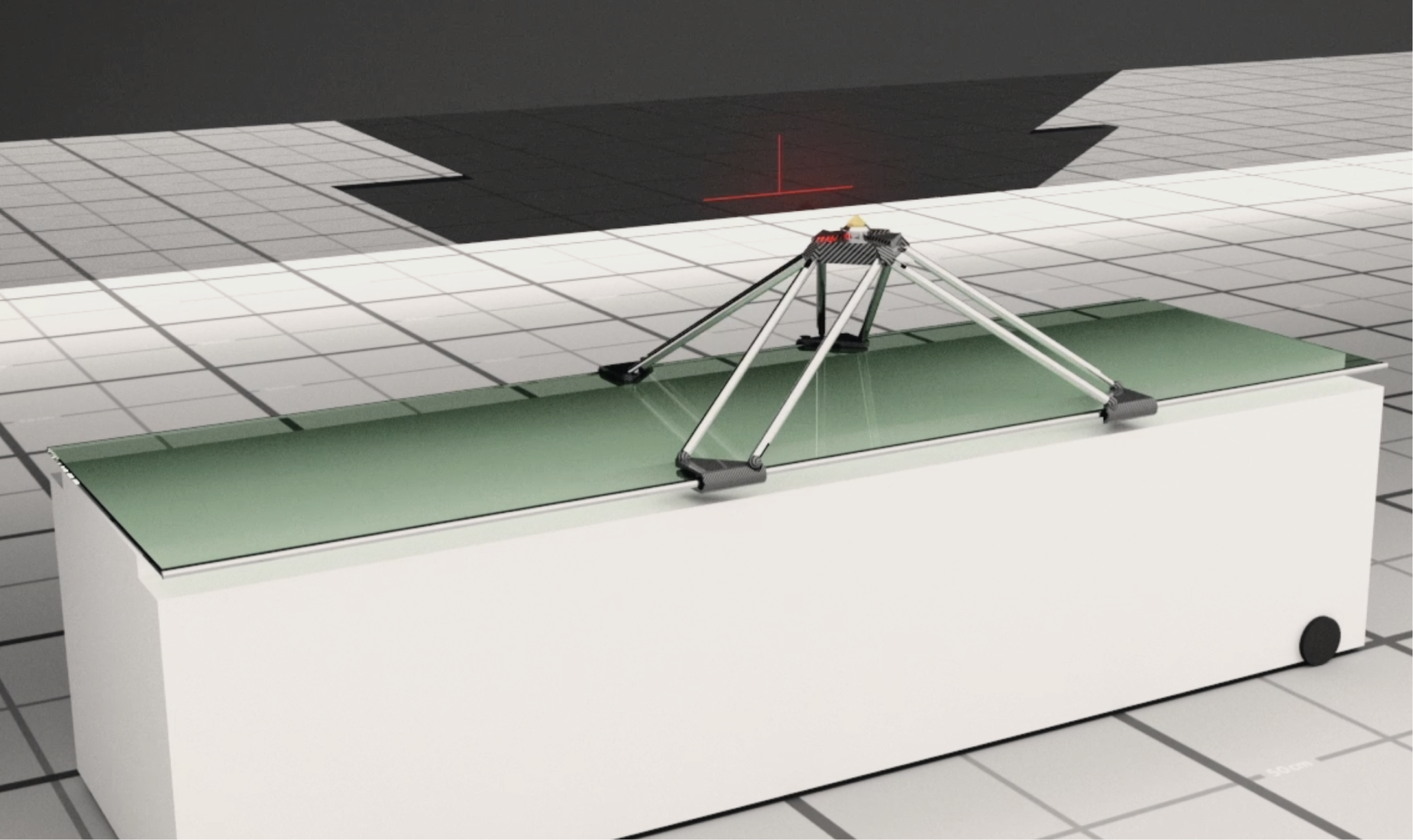

Three-stage positioning technology

This technology allows you to position the printer’s printhead relative to the part being manufactured with an error of 0.5 mm.

This makes it possible to eliminate the use of very expensive systems (lidars, 3D scanners), thereby significantly reducing the cost of equipment while maintaining high system accuracy.

Interactive model building

The developed software that allows you to place the model on the surface of the table inside the program, as well as the choice of accuracy and printing methods.

Using this software, the customer will adjust the parameters of the printing process to obtain an accurate result.